Improve consumer safety and speed time to market by minimizing errors, ensuring compliance, and managing recalls

60%

Cumberland、アートワークの承認時間を60%削減

1つのシステム

Supplyit は、現在すべての日常業務を処理するために単一のシステムのみを使用

当社を導入し、SAP と統合して以来、私たちは製造施設全体でラベル管理を拡大することができ、同時に新しいお客様の要望や追加の規制要件にうまく対応することができようになりました。

Tim Cukr 氏、McCormick & Company、IT 専門家

米国食品医薬品局(FDA)は、食品および内用医薬品における赤色3号の使用を、2025年1月15日をもって禁止しました。食品製品は2027年1月15日までに、内用医薬品は2028年1月18日までに再配合およびラベルの再表示を完了する必要があります。この変更により、製品ラベル、パッケージング、およびマーケティング資料に影響が及び、コンプライアンスを維持するためには、更新が不可欠です。

The food and beverage industry is prioritizing transparency, sustainability, and ethical sourcing. Consumers increasingly want to know what’s in their food, where it comes from, and how it was made—driving demand for clean labels, sustainability claims, and QR codes that deliver real-time, mobile-accessible product information. These trends support both compliance and consumer trust.

Automate product identification to avoid delays and reduce mislabeling and streamlining production

Drive product identification from critical business applications such as SAP, Oracle, and regulatory databases to improve data accuracy and consistency

Streamline product identification to meet global regulations like FSMA, 21 CFR Part 11, EU 1169, and Natasha's Law and avoid recalls and fines

Provide controlled access to labeling and artwork to ensure accurate first-time product identification and prevent costly and timely relabeling

Standardize and centralize product identification to meet corporate standards and support ongoing business growth - whether through new facilities, regional expansion, or M&A

Manage short links and QR codes to share dynamic content—such as sourcing, allergens, or sustainability data—while creating mobile-first consumer experiences

It’s all right there™

業界をリードするクラウドベースのラベル管理プラットフォーム、Loftware Cloud でラベリング業務を管理・拡大しましょう。ラベル管理を一元化し、コラボレーションを強化し、グローバルなサプライチェーン全体でのコンプライアンスを徹底します。

エンタープライズ ラベリングについて参照Loftware Cloud で拡張Streamline your packaging artwork management with automated workflows, built-in approvals, and real-time collaboration. Accelerate time-to-market and ensure regulatory compliance with Loftware Smartflow.

Smartflow の実際の動作をご覧くださいLoftware’s Connected Packaging enables brands to turn every product into an intelligent touchpoint, driving consumer interaction and unlocking real-time data across the supply chain.

Raise the bar on barcodes

人的ミスを排除し、生産停止時間を短縮

規制遵守のためのデータ駆動型ラベル管理

パートナーとサプライヤーにアクセスを拡張

アジャイルなサプライチェーンのための統合システム

追跡可能性と効率性のための一元管理

精度と効率を向上させます。ラベル管理とパッケージングのレビューサイクルに透明性と説明責任を導入し、リスクを軽減し、市場投入までの時間を短縮します。これにより、売上高を増加させながら販売管理費を削減できます。

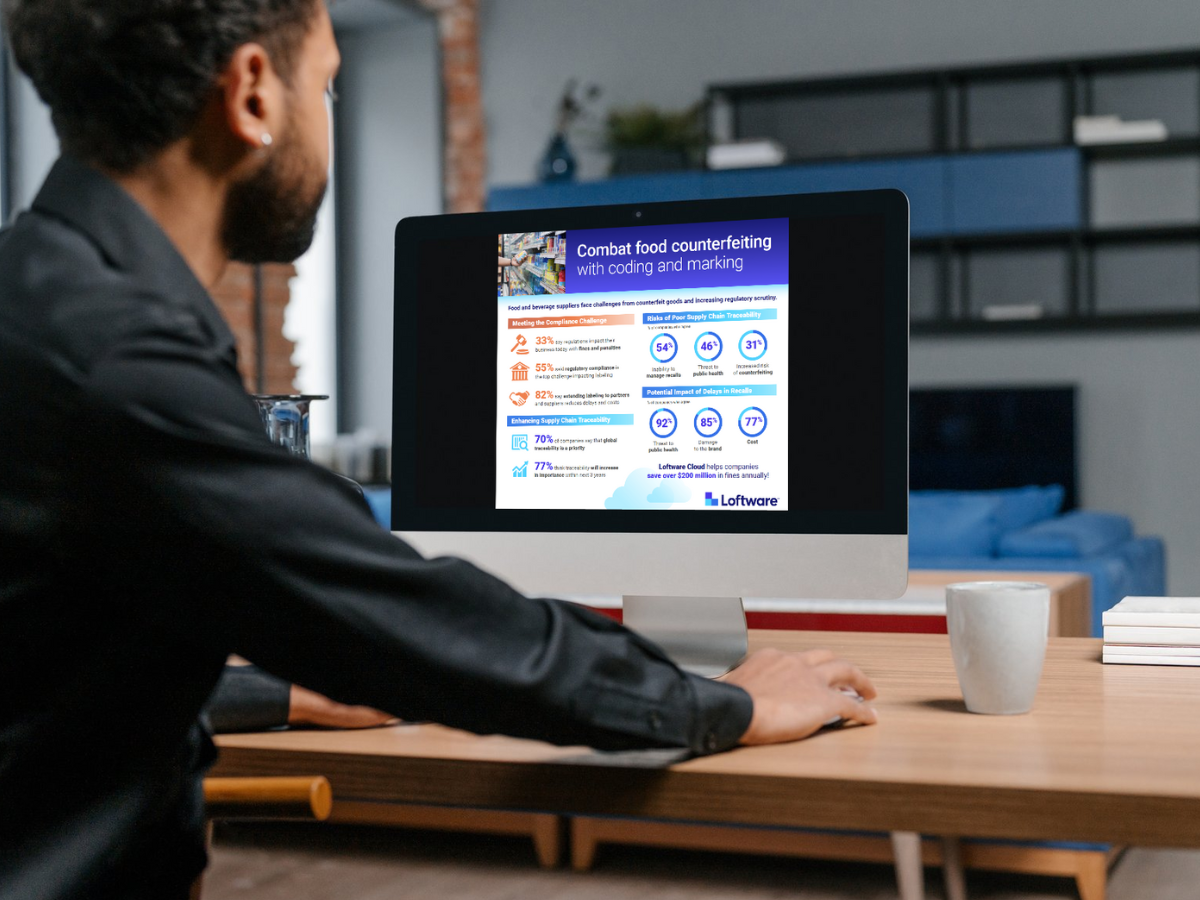

最近の調査によると、食品・飲料企業の77%が、今後3年以内にトラック&トレースの重要性が高まると考えています。インフォグラフィックをご覧になり、回答者が他にもサプライチェーンの持続可能性、偽造防止、規制の強化についてどのような意見を述べたかについて詳しくご確認ください。

Loftware Smartflow を導入したことで、Cumberland Packing Corp. はアートワークの承認時間を60%短縮し、再印刷コストで10万ドル以上の節約を実現しました。Loftware は当社のプロセスにおいて画期的な変革をもたらしました。

Sara Hoskow

ブランドマネージャー

Loftware Cloud 内には、エンドユーザーが時間を大幅に節約するのに役立つ機能が豊富に搭載されています。

Gabriel Molina

System Analyst

Loftware は、当社のすべての部門において、アイデアから実際の最初の生産工程までを一元化するのに役立ちました。すべてが Smartflow に統合されています。

Julissa Gutierrez

Lakeview Farms、マーケティング サービス コーディネーター

品質と生産の面において、当社はすべてのデータを一元管理し、現地で展開しています。これにより、常に正しいデータが印刷され、規制遵守が確保されています。

Lucy Webb

テクニカル マネージャー

自動化は、世界的な需要の急増に対応するため、食品・飲料サプライチェーンを再構築しています。この需要は、2050年までに2倍になると予想されています。クラウド技術は、予測、在庫管理、品質を向上させるとともに、戦略的な統合とコラボレーションを可能にします。

製造業者、供給業者、および販売業者に影響を与える主要な規制には、以下が含まれます。

動物実験において発癌リスクが認められたため、食品および内用医薬品への使用が禁止されました。

予防的な FDA 規制による食品由来の疾病防止法。

電子記録および電子署名が信用性、信頼性があり、紙の記録と同等であることを認める FDA の規則。

事前包装された食品において、明確なアレルゲン表示が義務付けられています。

バーコードと RFID 規格を活用してサプライチェーンのデータを改善します。